|

|

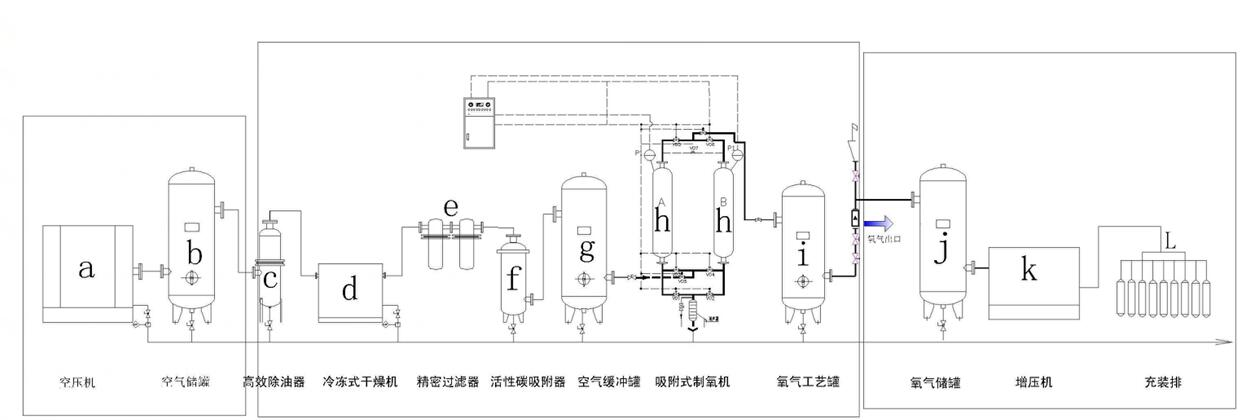

Introduction: HTO pressure swing adsorption oxygen generator is designed using PSA pressure swing adsorption principle. It uses high-quality oxygen molecular sieve as adsorbent, and directly separates and produces oxygen from the air at room temperature. It can be used for different industries and different users. For different requirements, provide personalized and professional oxygen production equipment to fully meet the gas requirements of different users. The HTO pressure swing adsorption oxygen generator has low investment and operating costs, and is suitable for the oxygen demand of various processes. It is the most effective and economical solution for customers to obtain unlimited on-site oxygen supply. Working principle: HTO pressure swing adsorption oxygen generator is an automatic equipment that uses zeolite molecular sieve as the adsorbent, and uses the principle of pressure adsorption and decompression desorption to adsorb and release oxygen from the air, thereby separating oxygen. Zeolite molecular sieve is a kind of spherical granular adsorbent with micropores on the surface and inside, which is processed by a special pore type treatment process, and it is white. Its pore type characteristics enable it to realize the kinetic separation of oxygen and nitrogen. The separation effect of zeolite molecular sieve on oxygen and nitrogen is based on the small difference in the dynamic diameter of the two gases. Nitrogen molecules have a faster diffusion rate in the micropores of the zeolite molecular sieve, and oxygen molecules have a slower diffusion rate. The diffusion of water and carbon dioxide in compressed air is not much different from that of nitrogen. The final enrichment from the adsorption tower is oxygen molecules.

Technical index: Oxygen output: 5-1000 Nm3/h Oxygen purity: 93±2% Oxygen pressure: 0.2-0.3Mpa Dew point: ≤-40℃ (under normal pressure) Main features of HTO variable pressure oxygen generator 1. The device process is streamlined, the structure is compact, and the equipment investment is low. 2. The device occupies a small area and can be used for indoor and outdoor operations. 3. The device is fully automatic control, convenient and quick to start and stop, and realize unattended operation. 4. The operation and maintenance cost of the device is much lower than that of cryogenic oxygen production. 5. The device has strong operation independence, good stability, high reliability, working under normal temperature and low pressure, and good safety performance. 6. The device has low energy consumption and low operating cost. Application scenario Steel cutting: oxygen enrichment for steel pipe and steel plate cutting in the field, mobile or small oxygen generator can meet the requirements Petrochemical industry: The oxygen reaction in the petroleum and chemical process uses oxygen-rich instead of air to carry out the oxidation reaction, which can improve the reaction speed and the quality of chemical products Electric furnace steelmaking: decarburization, oxygen-assisted combustion heating, foaming slag, metallurgical control and subsequent heating Glass production: oxygen-enriched explosion of activated sludge, oxygenation in pools and ozone sterilization glass melting, cutting, increasing glass output and extending furnace life Non-ferrous metal smelting: the smelting of copper, zinc, nickel, lead, etc. requires oxygen enrichment, and the PSA method is gradually replacing the cryogenic method Ore processing: used in gold and other smelting processes to increase the extraction rate of metals Aquaculture: used in large fish ponds to increase the oxygen content in the water, while inhibiting the growth of anaerobic bacteria in the water, preventing the deterioration of the pond water from threatening the living environment of fish |